Traceability is an indispensable need of supply chain in the pharmaceutical industry. The challenges faced by pharmaceutical organizations during the recent COVID pandemic have exposed the importance of traceability even further. According to a report by LogiPharma and BSI, Supply chain visibility stands out as the major challenge faced by the pharmaceutical industry. This is followed by issues with Goods distribution practices, Data integrity, Supplier quality, and supplier compliance management. The same report suggests that in the next three years, cost pressure, supplier compliance management, and regulatory policy changes will be the major challenge for the pharmaceutical industry. All these challenges impose greater risk of product recall which can be solved by ensuring an effective traceability system in the supply chain. Pharmaceutical products are quality sensitive and hence need continuous monitoring as they move in the supply chain. Traceability also helps to ensures that all the quality and regulatory guidelines set by governing authorities like WHO, DQSA, and FDA are complaint. Traceability helps to prevent the entry of fraudulent enterprises that can counterfeit products of any legitimate drug manufacturer. Having an end-to-end traceability helps drug manufacturers to have better control on their supply chain. This article highlights the challenges faced by pharmaceutical industry due to lack of product traceability and how GS1 India is changing the face of pharma supply chains with its traceability solutions.

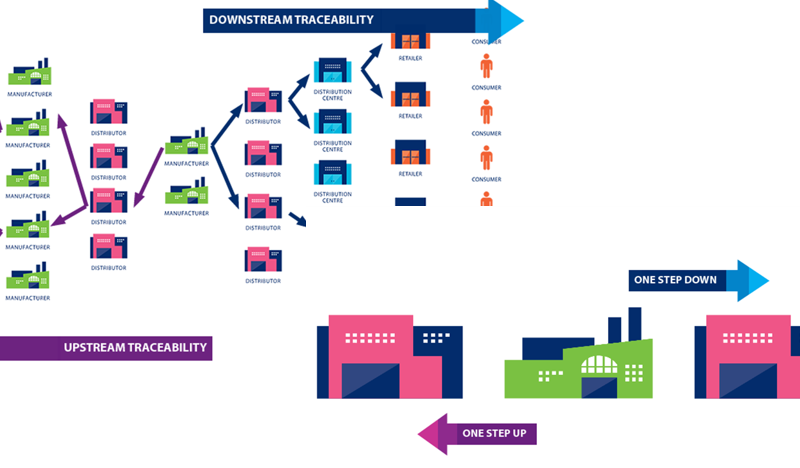

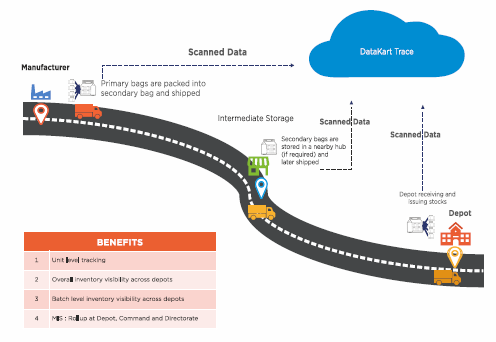

DataKartTrace is the track-and-trace solution of GS1 India, a non-profit organization set up by the Ministry of Commerce, Government of India, to authorize barcodes in India. According to GS1, Traceability is defined as a process that “enables you to see the movement of prescription drugs or medical devices across the supply chain. You can trace backwards to identify the history of the transfers and locations of a product, from the point of manufacture onwards. And you can track forwards to see the intended route of the product towards the point of care.”

Today, people are not just looking for transparency in terms of product quality, but they are also seeking answers to the questions like what is the place of manufacturing, when was it produced, how was the product tested, and what all ingredients does it contain. With transparency, it is easier to answer all these questions to the consumers and keep a record of how efficiently operations are happening in the supply chain.

Let us look at how GS1 India’s traceability service is helping the pharmaceutical industry safeguard its supply chain network.

Adherence to Compliance requirements:

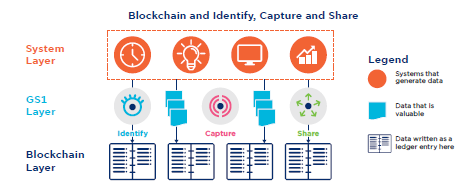

GS1 India complies with GS1’s Global Traceability Standard for Healthcare (GTSH), a process standard that provides a foundational framework that describes the traceability process and defines the minimum requirements for all stakeholders, independent from technologies, organization size, or operational sophistication. GS1 India also adheres to EPICS, a GS1 standard, which enables trading partners to share information about the movements and whereabouts of products and assets through the supply chain. Besides, GS1 India ensures compliance with the quality and legal requirements of the local government, FDA, FSSAI, etc. GS1 India helps comply with the track and trace guidelines issued by the Directorate General of Foreign Trade (DGFT) that help avoid the entry of spurious drugs at any point in the supply chain while exporting the drugs in foreign markets. DGFT mandates pharma manufacturers to mark their export consignment with GS1 authorized barcodes. The barcodes help the authorities cross-check the drugs’ manufacturing details at any point in the supply chain. GS1’s DataKartTrace is driven by various EU regulations and international safety laws.

International acceptability:

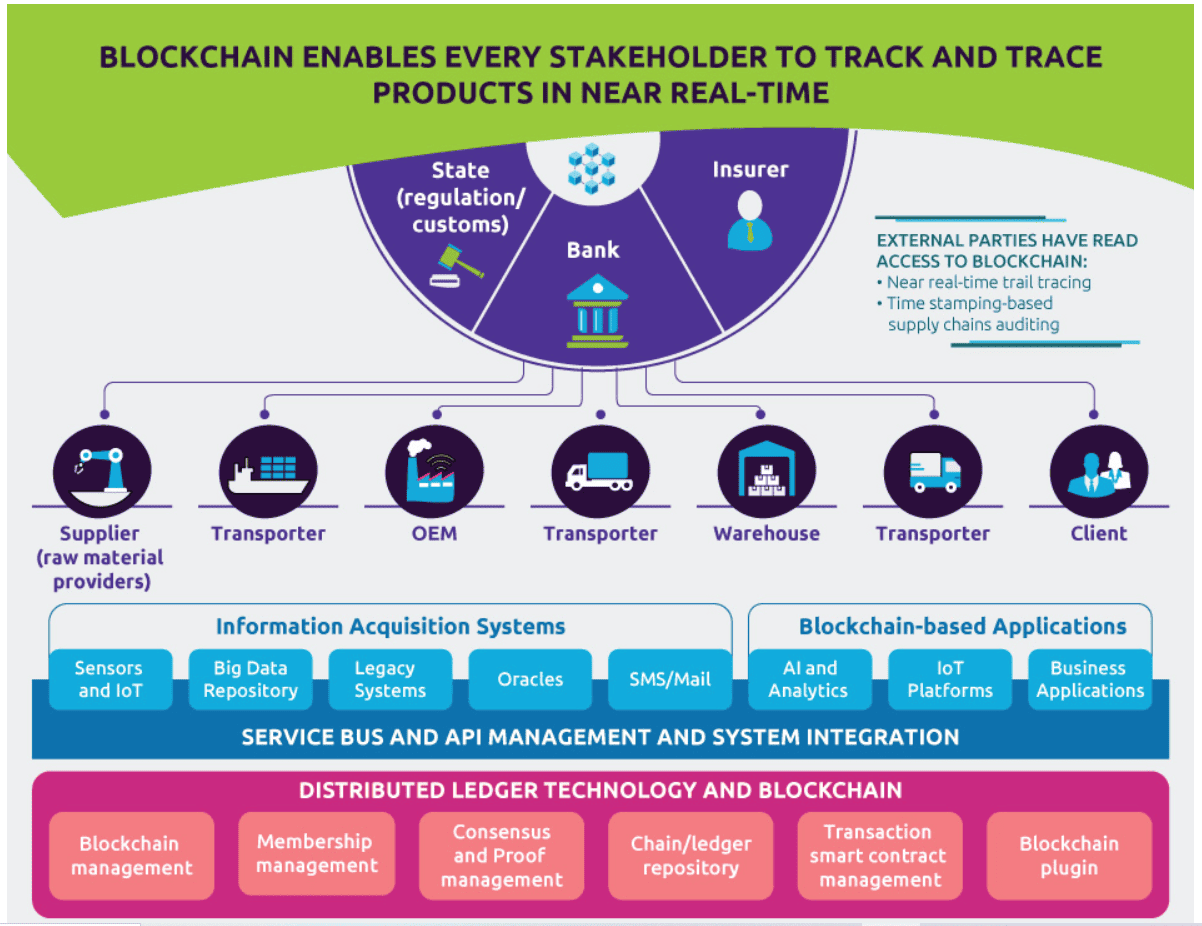

GS1 India’s DataKartTrace helps organizations get international acceptability for their products. GS1 India follows global standards for identifying, capturing, and sharing supply chain information; hence it meets the compliance requirements of various countries. DataKartTrace helps increase security, visibility, and control in the supply chain. Thus, by adopting GS1 traceability services, enterprises don’t need to stress their resources for managing numerous international regulations and licenses. GS1 India eases their work. With product GTINs, GS1 India helps trace the product back to its manufacturing plants, production lines, and production batch. It empowers the business owner to keep an eye on their contract manufacturers and suppliers.

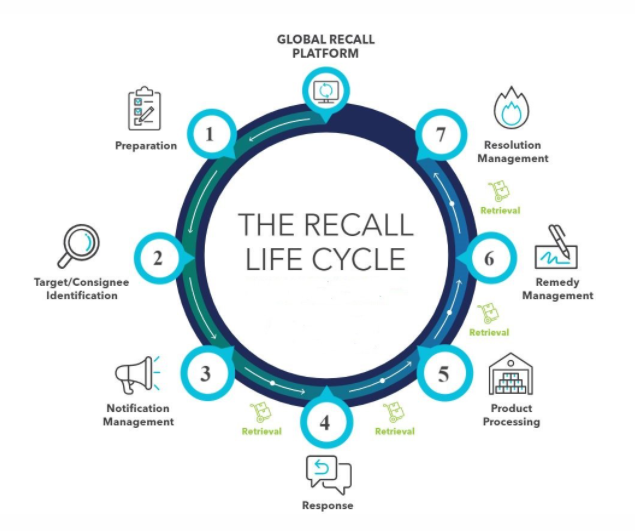

Product recall:

Product recall is the process of calling your products off the market in case of safety, legal or regulatory breach. Recall happens when an organization fails to comply with the guidelines and requirements set by the regulatory bodies such as FDA, FSSAI, or local government that can cause the consumer to suffer. Visibility, smooth and accurate flow of information across the supply chain, infrastructure availability, responsive information sharing, and logistics network are some of the necessities of an efficient product recall system. GS1 India’s traceability service helps the organization be recall-ready by ensuring a smooth flow of information, visibility, and responsiveness in the system. The pharmaceutical industry is more susceptible to product recall because stringent compliances are issued on them, owning to the question of public safety. GS1 India helps organizations prevent product recall by monitoring their product quality and legal licenses and safeguards them with traceability if product is recalled.

Product visibility:

DataKartTrace helps enhance visibility in the supply chain. Visibility is essential for fight product counterfeiting and ensuring consumer safety. It also helps to make strategic decisions for improving the efficiency of logistics and supply chain operations. Product visibility helps pharmaceutical organizations plan their cold supply chain where the drugs, consumables, and other medical supplies are highly sensitive to temperature and other environmental conditions. GS1 India ensures that the information is available to all the stakeholders well in time and inconsistent manner. GS1 India promises an affordable solution for maintaining precision and accuracy in the product information.

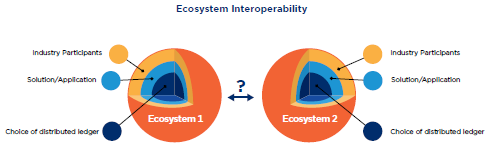

DataKartTrace is easy to implement and ensures interoperability by sharing the information in standard format overcoming geographical, jurisdictional, and language limits. The solution is customizable and are flexible as per the needs of customers and the complexity of the supply chain. To know more about DataKartTrace, contact us.

.png)

.png)

.png)